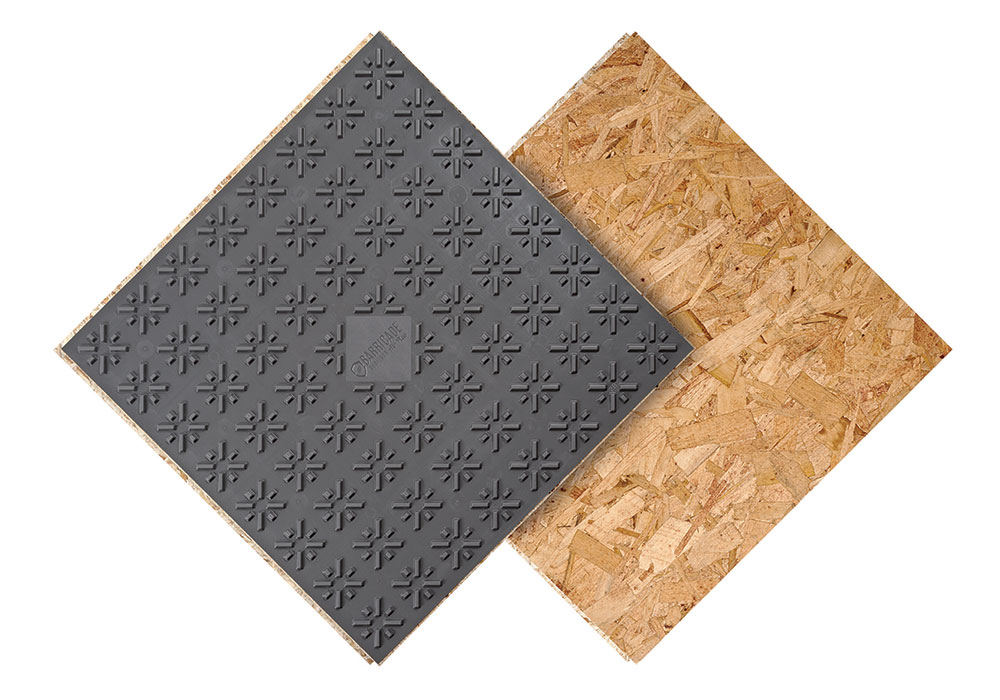

A subfloor is the structural layer that is attached to the floor joists below and finished flooring attaches directly on top. Standard A/C grade plywood (smooth on one side, rough on the other) can be used for subfloors but it is more common to use tongue-and-groove sheets that fit together to reduce movement and squeaks. Also available are OSB sheets (oriented strand board) which already have a tongue-and-groove edge.

There is debate about whether plywood or OSB is better as a subfloor but both are good materials and are acceptable when installed correctly. Each is available in 4’x 8’ or 4’ x 12’ sheets and at different thicknesses. The spacing of your floor joists will determine the thickness of the subfloor. The more widely joists are spaced, the thicker the subfloor required.

Both plywood and OSB sheets install similarly on top of the joists. Use as many full sheets as possible for optimum strength and make sure the ends are centered on the joists. Stagger sheets so that so that they don’t line up and make sure four sheets don’t meet at one point. Leave a 1/8 inch gap between sheets to allow for expansion.

Whether to use nails or screws to fasten a subfloor is a personal choice. Nails will fasten faster when using a nail gun but screws have a greater holding power. Whichever you choose, fasten the subfloor to the joists every 8 inches.

Construction adhesive can add another level of strength to your subfloor. Apply a bead of adhesive to the top of floor joists and on the tongue-and-groove edge of your plywood or OSB for maximum strength.

A good, strong subfloor should be solidly built and with no movement or flex. If your subfloor has movement, the result is a failure in the finished floor. Cracked floor tiles, broken floor grout, gaps between planks and squeaky flooring are usually the result of a weak subfloor.

Some types of flooring have specific subfloor requirements so read the entire manufacturers directions.

Have questions? Take advantage of our expertise to avoid mistakes. TIMBER MART has the advice and materials to build a strong subfloor that will last for years.